A Preface

The complete PCB process can be divided into 16 items, each process has its special characteristics requirements and practices, in addition to the whole production process has a variety of different environmental requirements (temperature, humidity, dust, acid and alkali resistance.. Etc.), and the good and bad environment is very different, so a complete PCB process is required to consider a variety of factors, but the collection of related process data is a very important information in the PCB process.

System description

This PAC machine control is mainly applied to the horizontal wet film coater for welding prevention in PCB wet process equipment. This machine is a key of the front PCB process, so many process data of the front process will be integrated in this station. Most of this part of the original machine and equipment is based on PLC as the main control core, so the relevant data in the centralized process is not an easy event. PLC mainly focuses on reliability and stability, which is also the main reason why this kind of machine has not been PC-BASED. However, in recent years, after the major PLC manufacturers successively launched the Controller with PAC(Programmable Automation Controller) as the core architecture, Machine equipment manufacturers began to think about how to introduce the original traditional PLC machine equipment into the PAC control core, the PAC's unique PC-Based characteristics (high-speed core computing, network, communication and VGA display and other integrated functions) as well as PLC characteristics of high reliability and stability into the machine equipment. Due to the highly integrated PAC control core, the professional knowledge of the original PLC machinery and equipment manufacturers, coupled with the consideration of production costs and other factors, the manufacturers of these production equipment have significantly different machine changes and innovations. The development of composite machine, in the traditional PLC and CNC machine equipment to achieve integrated function and human-machine interface beautification and can reduce the development cost of machine equipment, so the manufacture and design of machine equipment, began to PLC another new era PAC control core direction to think about the future of the machine.

PCB horizontal wet film coater characteristics requirements

Since the PCB board manufacturing process is process specification, the feed port of this machine will be combined with the discharge port of the previous process, and because the PCB board has a variety of different sizes, so when the machine after feeding into the next process, the whole process must have manual and automatic conversion operation function. Update process temperature, feed speed and any abnormal history records. The plate width error in the whole process must be in specific requirements, the fixed speed of the transmission material should be stable, the absolute position recovery detection ability of the coating mechanism after abnormal occurrence and the PID temperature control ability of the baking process are the main core of this equipment, and the past equipment manufacturers are the use of PLC core design and development machine, So in advance of the planning and design and distribution personnel communication and equipment after the maintenance is a big challenge on integration, in addition, on the cost of speculation if added to the cost of the man-machine interface then the cost of this machine is not low and it is not easy to modify the man-machine interface in the future, let alone to do the process data integration function; Therefore, these core functions of PAC prompt equipment manufacturers to have high expectations for PAC. In addition, each equipment manufacturer does not want to lag behind others in the design technology of the machine, so the PAC trend is about to become the mainstream in the machine equipment development industry!

The Solution

Due to the hope to be able to integrate the relevant data before and after the process can be unified, and to achieve the establishment and storage of data, so the relevant communication integration is very important, and this part is the PLC is not easy to solve the problem, the PAC provided by Hongge technology in positioning is a combination of PLC+PC-Based, Therefore, the need for this integration can be easily achieved; In addition, we also implant various software tools of EzProg-I into this specific PAC controller, so as to provide customers with more convenient and faster software construction, design and development tools for the machine design. After EzConfig I\O planning, we can synchronize the main control program design and wiring test to the final verification test. Hongge technology also provides a related man-machine interface development software EzHMI, its support machine equipment designers can be very simple and flexible way to design their own man-machine interface, and man-machine interface expansion can also be very fast to complete.

System architecture comparison

Traditional architecture (human-machine interface +PLC core) vs ICP DAS PAC Architecture (WinCon+Touch Panel+I-8094F+ FRnet DI\O):

Traditional PLC architecture

Hongge Technology PAC architecture

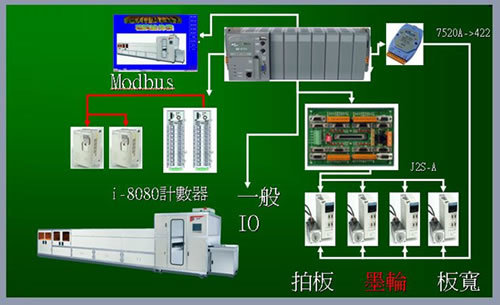

Hongge technology architecture diagram features

Hongge Technology uses the communication integration ability to convert the variable frequency motor control from AI\AO control to communication control, which improves the simulation interference problem caused by the power distribution and power environment for equipment designers. The PAC of Hongge Technology has VGA capability of standard PC, and provides EzHMI [ActiveX component] development kit, in addition to simplify the machine designers to develop the difficulty of man-machine interface, while saving the high cost of man-machine interface development, so that the original man-machine interface is not only larger and more beautiful, And the original use of PLC system to develop nearly 100 pages of complex man-machine interface operation procedures simplified to about 30 pages. ? Hongge technology in PAC controller value into the EzConfig software tool, so that the machine designers do not need to develop any software, that is, you can use EzConfig to do a variety of I\O point planning, and can produce I\O point planning table to facilitate distribution personnel to complete the distribution, and can immediately do physical testing; The software designer can start the design and development of the machine according to this I\O point planning table. When both are completed, the machine can be tested directly, which reduces the communication problems between software and hardware personnel. ? Hongge PAC provides shaft control module, general I\O module and FRnet distributed I\O module, which can meet the needs of customers in the design of machinery and equipment, and FRnet distributed I\O module can reduce the distribution cost, reduce the maintenance cost. ? The PAC of Hongge Technology has communication and built-in network functions, which can realize the combination of the upper and lower levels of database management, and has a simpler planning than the traditional PLC.

Conclusion

PCB industry is a combination of traditional and modern technology manufacturing industry, it is the cornerstone of all science and technology research and development, but because of the change of the market, also make it have different needs, which is also a lot of traditional industry changes in recent years, in order to cope with such changes, it triggered the production factory has different needs, relatively also let the machine equipment manufacturers have different recognition, And have a different idea, plus the current some PLC big factory also continue to develop PAC controller, so PAC will be another controller trend after PLC, and this trend will be big and fast, in this huge trend, you will need a close to your controller supplier, so that your new machine has a different life, Hongge Technology is the earliest and most committed to PAC technology research and development of PAC controller suppliers in Taiwan, our efforts and results are obvious, and we look forward to the trend of PAC can cooperate with you in the industry advanced.